Sol Oriens, LLC

6725 Academy Road NE

Albuquerque, NM 87109

505.717.8001

6725 Academy Road NE

Albuquerque, NM 87109

505.717.8001

At Sol Oriens, we have decades of experience in finding, developing, and inserting technology into military systems. In fact, this skill is one of the cornerstones of our prior success. In past years, we dealt in microelectronics, directed energy, radar, communications, sensors, and other supporting technology.

Technology development is a skill that borders on being an art form. It requires several resources that are difficult to acquire and maintain – personnel with skill, vision, and interest; facilities that will allow experimentation and development in a safe and appropriate environment; and equipment that allows computation, simulation, prototyping, assembly, testing, and assessment. And, of course the time and dollar resources that are required to do this work very well.

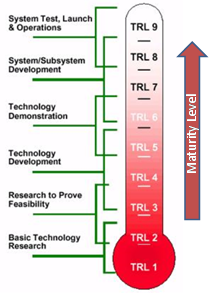

Technology Readiness Levels (TRLs) are best practices measures we use to assess the maturity of evolving technologies (devices, materials, components, software, work processes, etc.) during their development and in some cases during early operations. Nominally, when a new technology is first invented or conceptualized, it is not suitable for immediate application. Instead, new technologies are usually subjected to laboratory development and experimentation, continuous refinement, and increasingly realistic testing. Once sufficiently proven through increasingly stringent testing, a technology may be ready for use in a system.

Sol Oriens helps DOE and their prime contractors and stakeholders advance the maturity of interesting technology, assess the maturity and risks of specific technologies, plan development paths to carry a technology forward in TRL and develop both risk handling strategies for high technology products and alternatives to individual technologies if they don’t work out.

Sol Oriens completes Technology Readiness Assessments (TRAs), systematic, metrics-based processes to assesses maturity and risk associated with critical technologies proposed for Major Defense Acquisition Programs (MDAPs). The details of this are seemingly arcane, viewable here . We help with these assessments, as subject matter experts and team members, providing fact-based information that Program Managers can use to decide on technology.

We also manage Technology Development, Technology Maturation Planning, and Risk Assessment for DOE using specific DOE criteria and guidelines specific to nuclear weapons and systems.

| TRL | Definition | Description | Supporting Information |

|---|---|---|---|

| 1 | Basic principles observed and reported. | Lowest level of technology readiness. Scientific research begins to be translated into applied research and development (R&D). Examples might include paper studies of a technology’s basic properties. | Published research that identifies the principles that underlie this technology. References to who, where, when. |

| 2 | Technology concept and/or application formulated. | Invention begins. Once basic principles are observed, practical applications can be invented. Applications are speculative, and there may be no proof or detailed analysis to support the assumptions. Examples are limited to analytic studies. | Publications or other references that out-line the application being considered and that provide analysis to support the concept. |

| 3 | Analytical and experimental critical function and/or characteristic proof of concept. | Active R&D is initiated. his includes analytical studies and laboratory studies to physically validate the analytical predictions of separate elements of the technology. Examples include components that are not yet integrated or representative. | Results of laboratory tests performed to measure parameters of interest and comparison to analytical predictions for critical subsystems. References to who, where, and when these tests and comparisons were performed. |

| 4 | Component and/or breadboard validation in a laboratory environment. | Basic technological components are integrated to establish that they will work together. This is relatively “low fidelity” compared with the eventual system. Examples include integration of “ad hoc” hardware in the laboratory. | System concepts that have been considered and results from testing laboratory-scale breadboard(s). References to who did this work and when. Provide an estimate of how breadboard hardware and test results differ from the expected sys-tem goals. |

| 5 | Component and/or breadboard validation in a relevant environment. | Fidelity of breadboard technology increases significantly. The basic technological components are integrated with reasonably realistic supporting elements so they can be tested in a simulated environment. Examples include “high-fidelity” laboratory integration of components. | Results from testing laboratory breadboard system are integrated with other supporting elements in a simulated operational environment. How does the “relevant environment” differ from the expected operational environment? How do the test results compare with expectations? What problems, if any, were encountered? Was the breadboard system refined to more nearly match the expected system goals? |

| 6 | System/subsystem model or prototype demonstration in a relevant environment. | Representative model or prototype system, which is well beyond that of TRL 5, is tested in a relevant environment. Represents a major step up in a technology’s demonstrated readiness. Examples include testing a prototype in a high-fidelity laboratory environment or in a simulated operational environment. | Results from laboratory testing of a prototype system that is near the desired configuration in terms of performance, weight, and volume. How did the test environment differ from the operational environment? Who performed the tests? How did the test compare with expectations? What problems, if any, were encountered? What are/were the plans, options, or actions to resolve problems before moving to the next level? |

| 7 | System prototype demonstration in an operational environment. | Prototype near or at planned operational system. Repre- sents a major step up from TRL 6 by requiring demonstration of an actual system prototype in an operational environment (e.g., in an air- craft, in a vehicle, or in space). | Results from testing a prototype system in an operational environment. Who per- formed the tests? How did the test com- pare with expectations? What problems, if any, were encountered? What are/were the plans, options, or actions to resolve problems before moving to the next level? |

| 8 | Actual system completed and qualified through test and demonstration. | Technology has been proven to work in its final form and under expected conditions. In almost all cases, this TRL represents the end of true system development. Examples include developmental test and evaluation (DT&E) of the system in its intended weapon system to deter- mine if it meets design specifications. | Results of testing the system in its final configuration under the expected range of environmental conditions in which it will be expected to operate. Assessment of whether it will meet its operational requirements. What problems, if any, were encountered? What are/were the plans, options, or actions to resolve problems before finalizing the design? |

| 9 | Actual system proven through successful mission operations. | Actual application of the technology in its final form and under mission conditions, such as those encountered in operational test and evaluation (OT&E). Examples include using the system under operational mission conditions. | OT&E reports. |